Automotive

seat assembly

Hook and loop fasteners for seat assembly

For over 30 years, our hook and loop fastening solutions have been used by automotive OEMs and suppliers for seat assembly.

To improve productivity on your lines, our APLIX experts have developed ergonomic fastening solutions that facilitate installation while offering design flexibility.

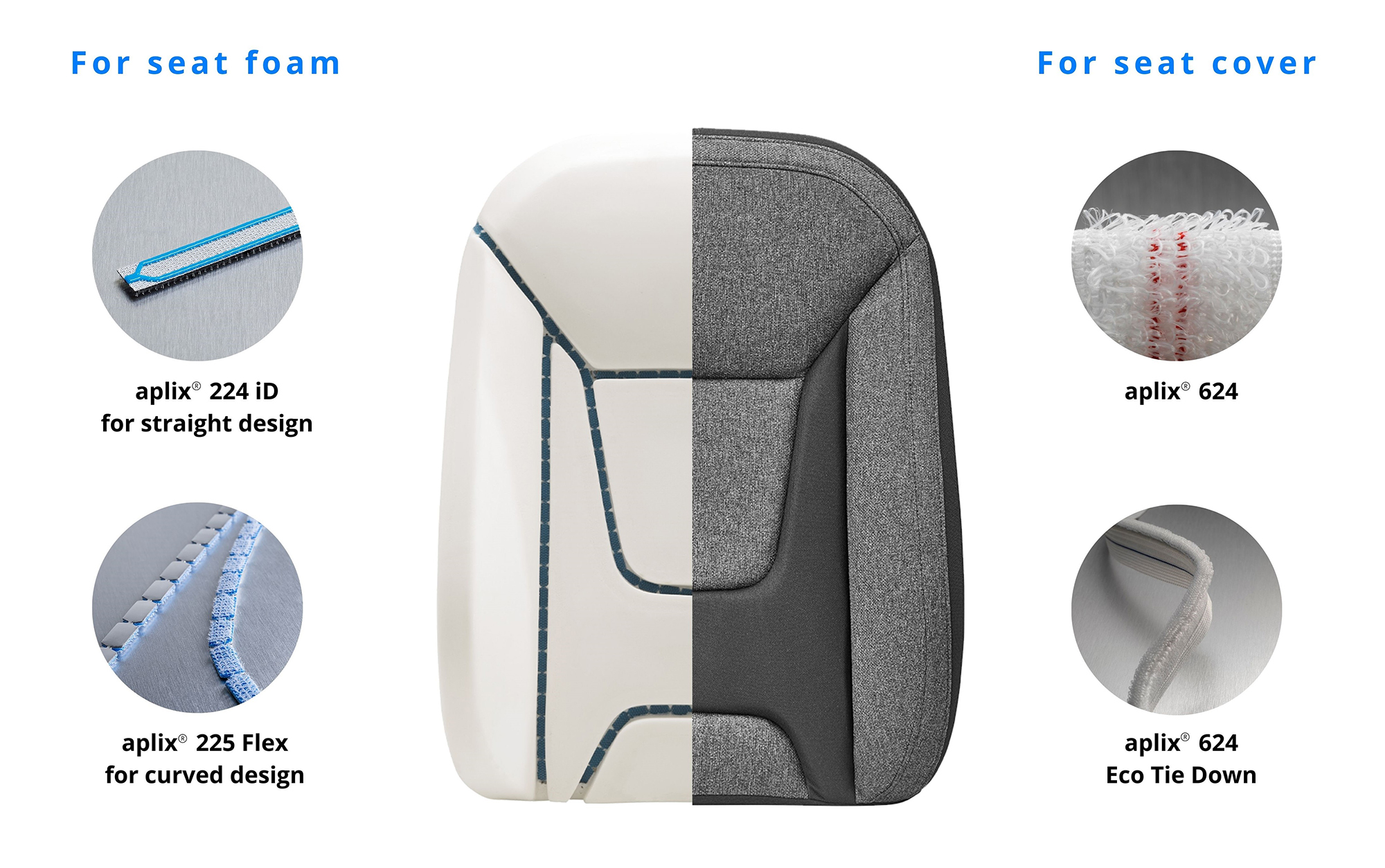

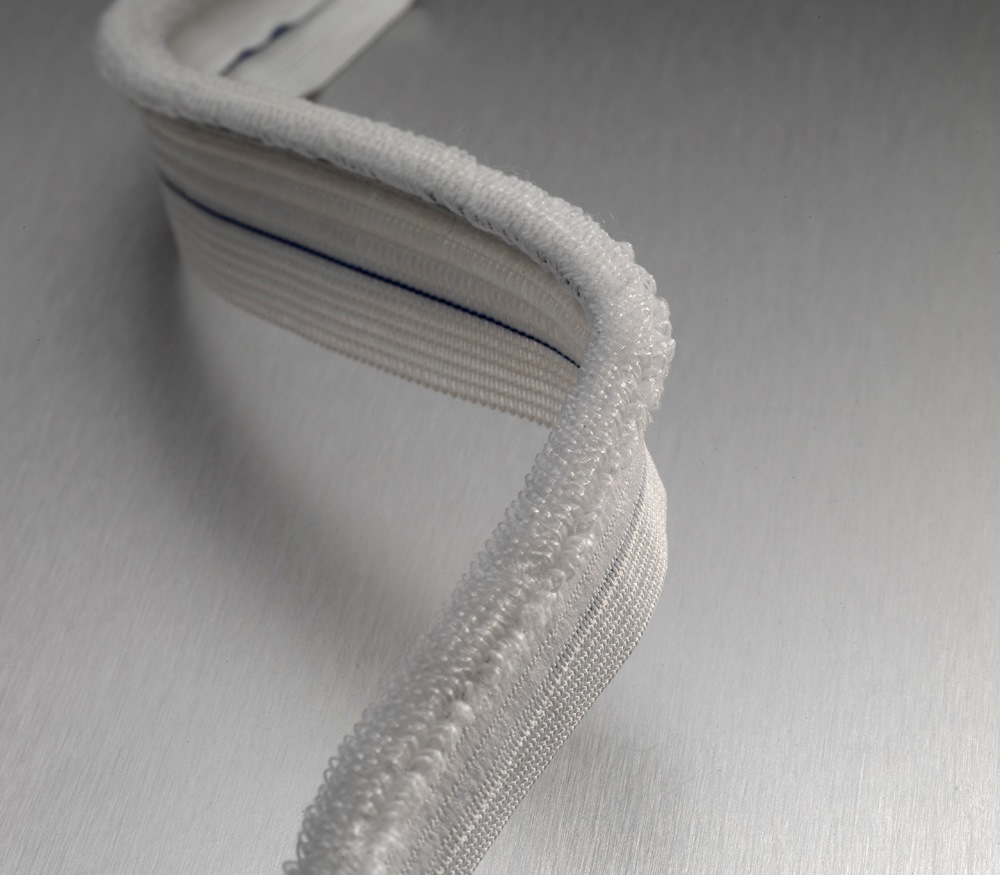

APLIX offers a wide range of fasteners products designed to be moulded into seat foam. These products are suitable for straight or curved car seat designs. For the seat cover, APLIX has developed soft and flexible tapes, made up of knitted loops, designed to be wound and sewn around the seat cover. The assembly of these 2 components ensures a reliable fit and optimum comfort for the end user.

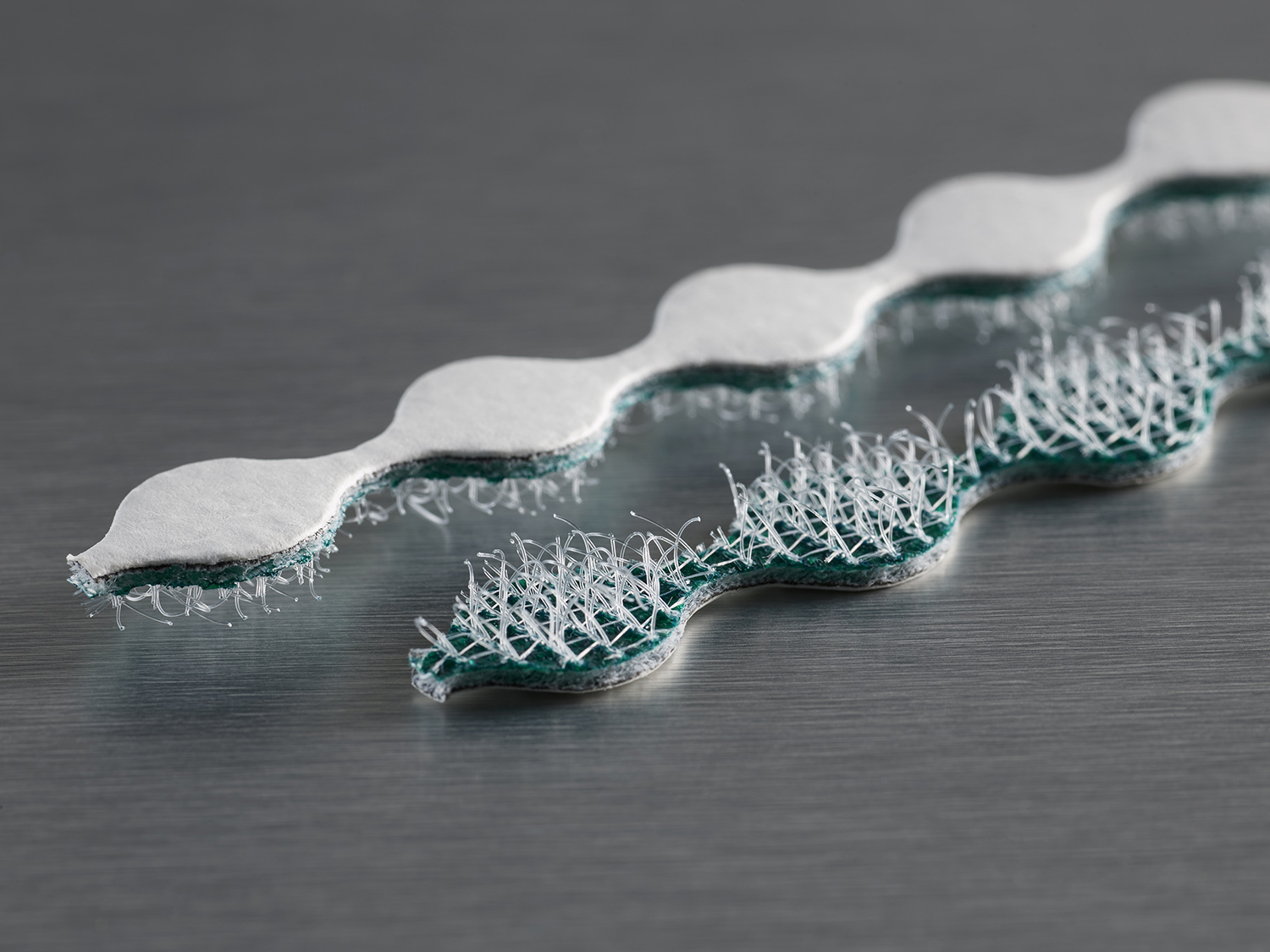

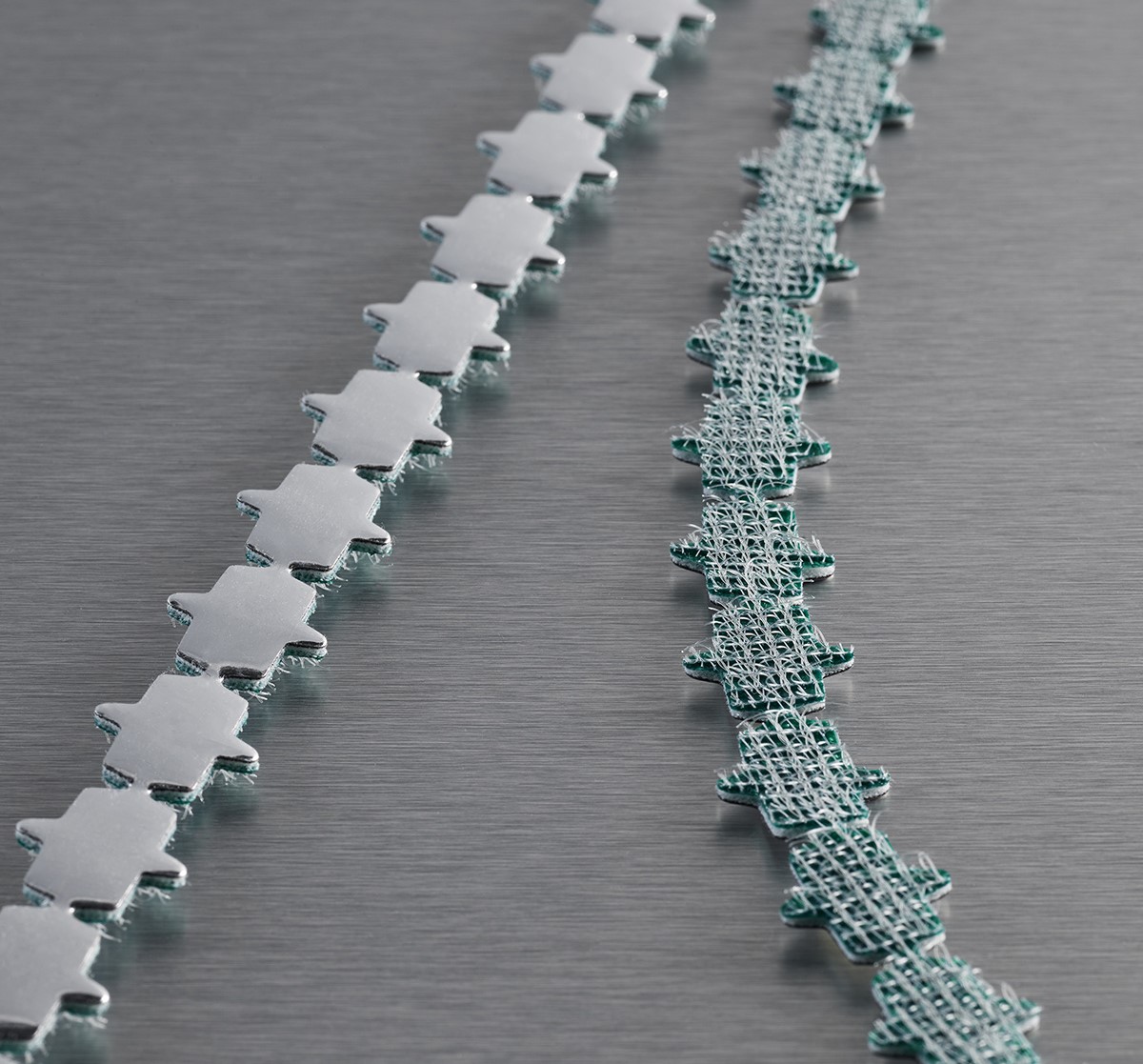

To support the transition to autonomous and electric vehicles with more spacious and streamlined interiors, APLIX is innovating with a new fastening solution adapted to slim seats with a 3D or curved design.

Our self-gripping products are available in a variety of sizes, shapes and adhesive strengths, allowing great flexibility in applications. Thanks to our R&D department, we regularly develop innovations that improve the performance and durability of our solutions, so that we are always at the forefront of the automotive sector's requirements.

Key benefits

- Enhanced comfort even with reduced foam thickness

- Improved ergonomics

- Design flexibility (concave, straight, 3D…)

- Reliable fastening solution

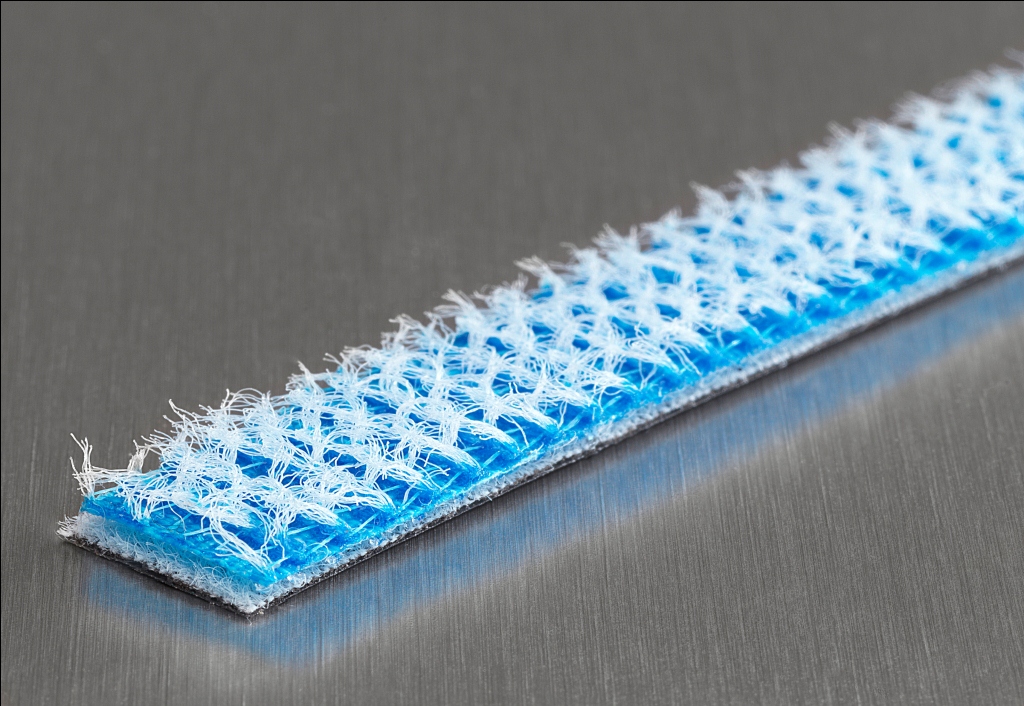

Our products for the seat foam

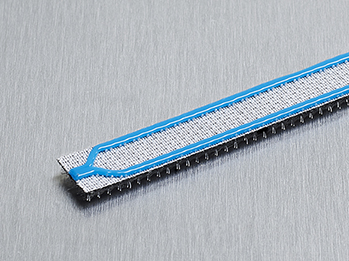

For straight design

Our products can be used in very narrow trenches (min: 8mm) allowing very aesthetic design. APLIX has developed specialty backing to provide optimal bond to various foam formulation.

aplix® 224 iD

aplix® 224 Foam

aplix® 225 Long Loop

aplix® 225 Multi Loop

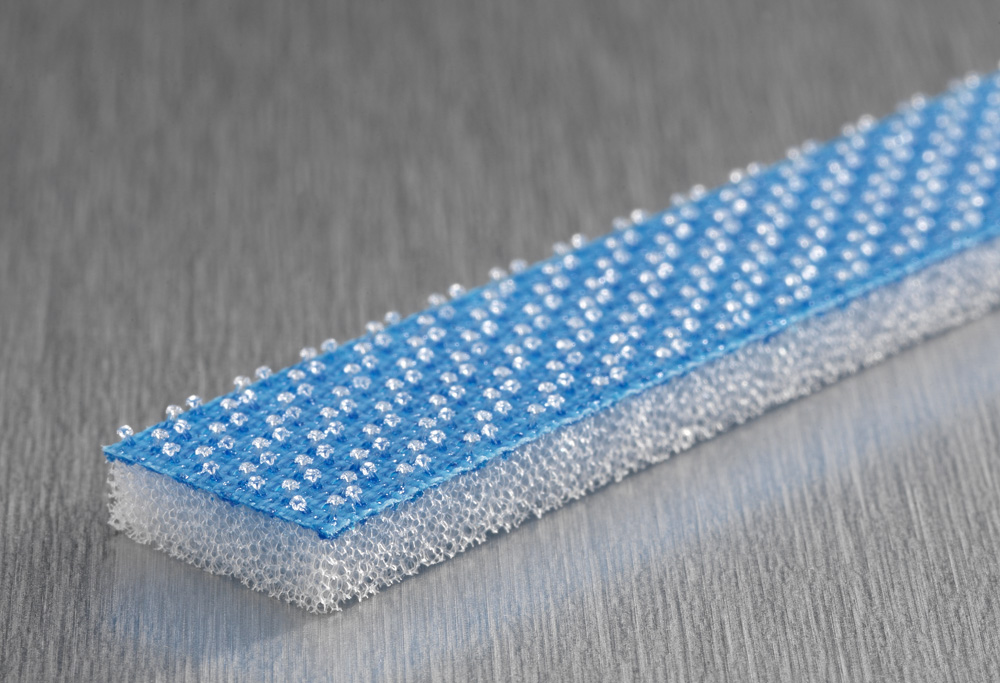

For curved design

APLIX solutions allow for free design including high curve definition in 2D and 3D.

aplix® 225 FLEX 2D

aplix® 225 FLEX 3D

aplix® 225 FLEX 4D

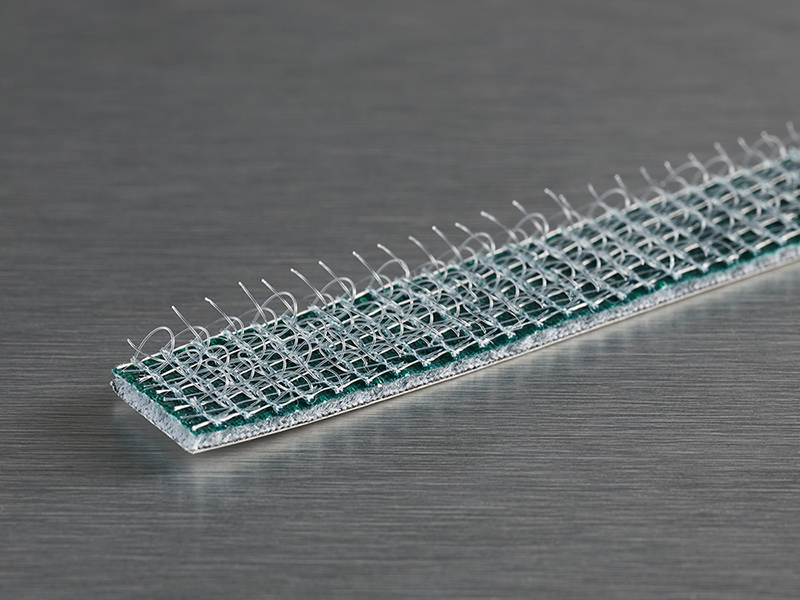

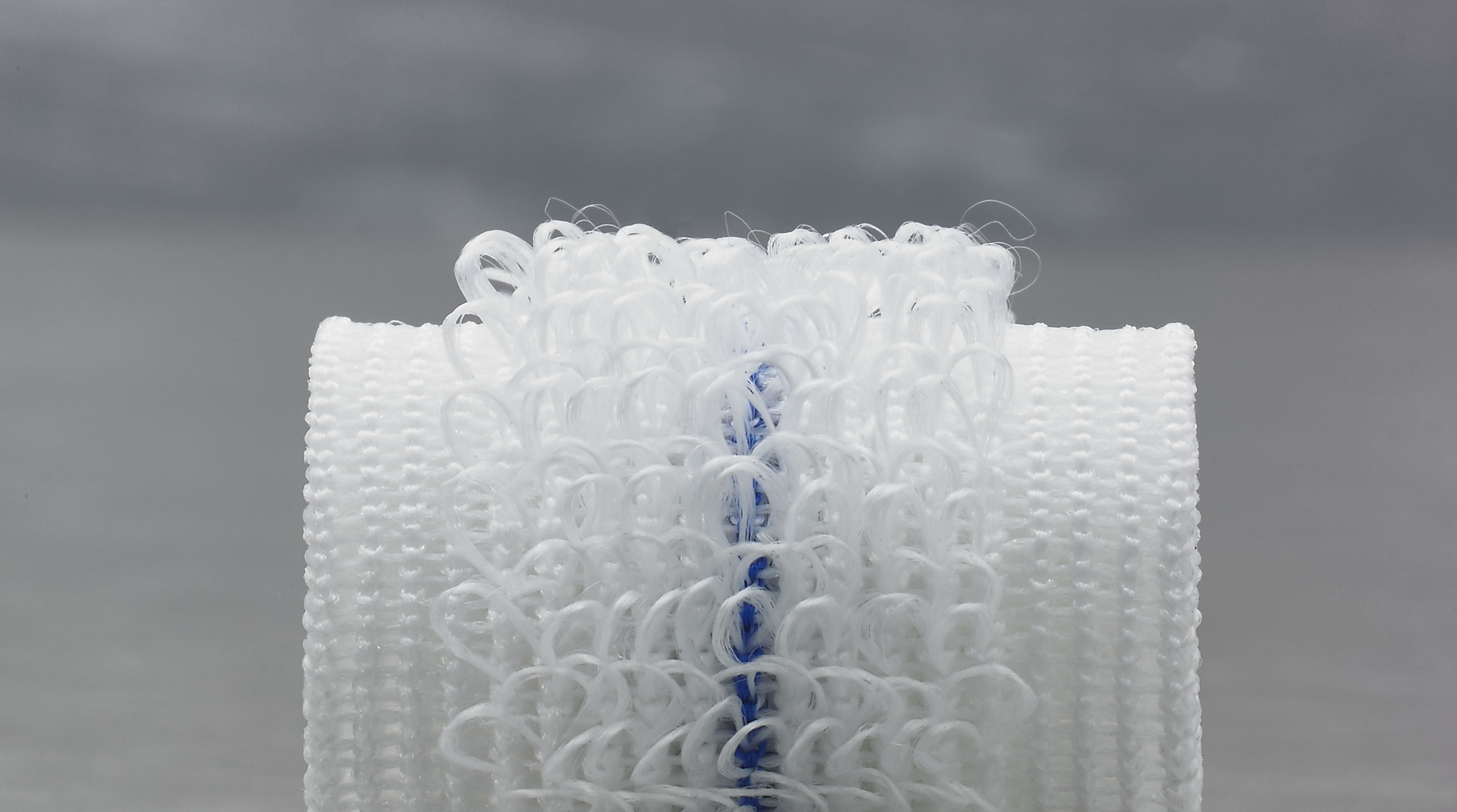

Our products for the seat cover

Knit loop products that can be wrapped around a join seam or sewn into a specific area to mate aplix® mold-in products. Various widths available upon request.

aplix® 624

aplix® 624 Fire retardant

aplix® 624 Eco Tie Down

Certifications

- FMVSS-302

Discover our solutions

for headliners & sunroofs

APLIX offers a global solution to affix headliner to sunroof modules without bezels for a better design.